Normal Vacuum Tube

Description

Solar vacuum tubes as the heart of the Jinyi solar water heaters are applied to absorb sunlight and convert it into usable heat.

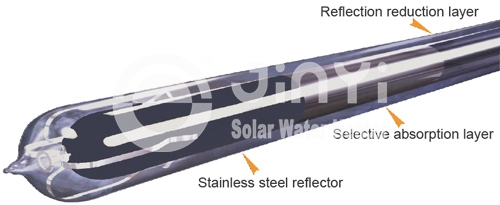

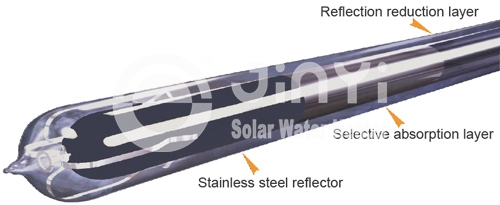

Referred to as the twin-glass tube or all-glass tube, the normal vacuum tube is essentially two glass tubes that are fused at the top and bottom. The inner tube has a solar absorbing coating, and the space between the two tubes is evacuated to form a vacuum.

Solar vacuum tubes are the absorber of the solar water heaters. They collect solar energy and convert it into heat for use in water heating. There are different kinds of evacuated tubes used in the solar industry. Our solar collectors adopt the most normal vacuum tubes due to their reliability, performance and low manufacturing cost. The solar vacuum tubes have already been used for years in Germany, Australia, France, Japan, Canada, China and the UK.

Structure of Normal Vacuum Tube

1. The solar vacuum tubes are made from a type of glass called borosilicate. The borosilicate glass is very strong and has excellent light transparency (>92% @ 1.6-2.2 mm thick).

2. The wall thickness of the glass greatly affects the strength, longevity and the cost. Jinyi normal vacuum tubes are custom made according to strict requirements that exceed the industry standards, including a 1.6-2.2mm thick wall ensuring excellent strength and resilience to hail impact.

3. In order to confirm the strength of the tubes, each batch of evacuated tubes assembled in our factory have randomly selected to be tested by dropping a 30mm / 1.2" diameter steel ball onto the tube from various heights.

4. The solar vacuum tubes are the core component of the solar water heater, just like an automobile engine or the computer CPU. Its performance lies on the actual film coating technology.

Advantages of our Normal Vacuum Tube

1. The solar vacuum tubes feature in excellent absorbing performance, low heat loss and super heat preservation. They are especially adapted to severely cold regions.

JINYI has successfully introduced the advanced solar selective coating, which can realize greater heating efficiency and better thermal stability. The solar selective coating absorbs most solar radiation as well as suppresses the thermal emittance loss from the coating. Adopting DC magnetron sputtering technology, the absorptance of 0.88-0.92 and emittance of 0.04-0.08 has been achieved. The main absorbing wavelength ranges from 0.35μm to 3.0μm

2. Excellent resistance of burst.

We have improved the molecule structure of plated selective coating and introduced DC magnetron sputtering technology, so the highest working temperature of the solar vacuum tube can reach 300℃. This can effectively prevent the coating from bursting, aging, discoloring, function attenuating because of long time burn under the sun, and also can prolong its life span to 15 years.

Furthermore, the special material plated on tube coating is activated promptly once sun irradiates. The upper surface of semi-cylinder of tube heated by sunshine directly, and the under surface heated by reflected ray at the same time, with different temperatures, so the thermal force propels the water to cycle in the tube rapidly. Consequently, the water circulation in the tube which is made of toughened high borosilicate 3.3 glass balances the temperature and prevents tube from burst.

3. Excellent resistance of corrosion, long life span (up to 15 years)

Our solar vacuum tubes use standard Pyrex high borosilicate glass with coefficient of linear expansion 3.3×10-6/℃, complying with international ISO1776 acid proof Grade 1, ISO695 alkali proof above Grade 2. This normal vacuum tube can resist the hailstone with diameter 25mm, and the pressure 1MPa.

4. The evacuated tubes enable to reduce the fouling on the tube wall and keep the water clean.

5. Solar vacuum tubes are aligned in parallel, and the angle of mounting depends on the latitude of your location.

Parameters of Normal Vacuum Tube

| Structure |

All-glass double-layer coaxial |

| Tube material |

High quality borosilicate glass 3.3 |

| Outer tube diameter and thickness |

Φ=47±0.7mm & =1.6mm

Φ=58±0.7mm & =1.6mm

Φ=70±0.7mm & =2mm |

| Inter tube diameter and thickness |

Φ=37±0.7mm & =1.6mm

Φ=47±0.7mm & =1.6mm

Φ=58±0.7mm & =1.6mm |

| Length of solar vacuum tube |

500mm 800mm 1500mm 1800mm

1900mm 2000mm 2100mm |

| Absorptive coating |

Structure |

AL/N/AL |

| Sediment method |

Magnetron sputtering plating |

| Absorptance |

a=0.88-0.92(AM1.5) |

| Emittance ratio |

Σn:=0.04-0.08(80℃?℃) |

| Vacuum quality |

p ≤ 5.0 × 10-2 Pa |

| Stagnation parameter |

Y=250-260M2. ℃/kw |

| Solar irradiation under stagnation |

Φ47 H≤3.7MJ/m2, Φ58≤4.7MJ/m2 |

| Average heat loss coefficient |

ULT=0.78W(m2.℃) |

| Lifetime |

>15years |

| Hail resistance |

Φ25mm/Φ40mm |

Jinyi Solar Energy Technology Co., Ltd. is a professional manufacturer and supplier of normal vacuum tubes in China. Besides solar vacuum tubes, we have solar thermal collectors, solar storage tanks, solar water heaters and their accessories for sale. Till now, we’re able to annually output 20 thousand heat pipe solar collectors, 5 thousand U pipe evacuated tube solar thermal collectors and 30 thousand non-pressure solar water heaters. If you are interested in our solar vacuum tubes, please contact us.