Heat Pipe Vacuum Tube

Description

Heat pipe vacuum tubes seem like a new concept, but you probably use them every day and don't even know them. Laptop computers often utilize small heat pipes to conduct heat away from the CPU, and air-conditioning system commonly uses them for heat conduction. In the Jinyi JHC and JMC solar collectors, the heat pipes are used to transfer heat from the solar evacuated tubes up to the header pipe that is housed in the insulated manifold box.

Structure & Operation of Heat Pipe Vacuum Tube

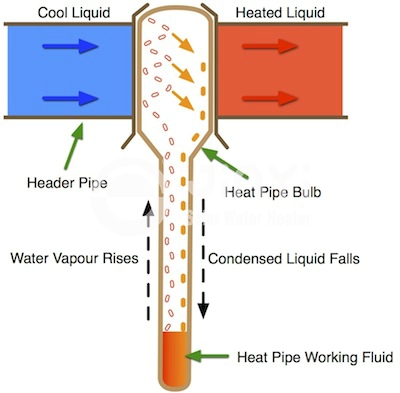

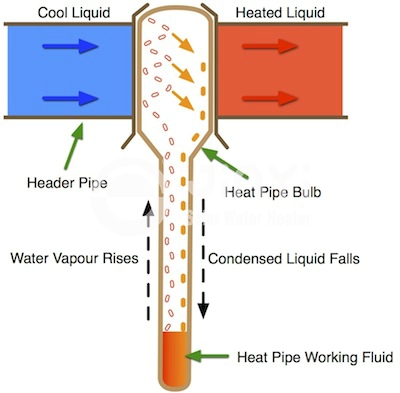

1. The heat pipe design contains a long hollow copper pipe with a larger diameter bulb at one end. A small amount of high purity water is added into the heat pipe and then heated to high temperatures to evacuate any air from within the space. The result is a vacuum, similar to the space between the glass walls of the solar evacuated tube.

2. In a heat pipe vacuum tube, the vacuum is not used for insulation, but rather to alter the behavior of the liquid inside. At sea level, the water boils at 100oC / 212oF, but if you climb to the top of a mountain the boiling temperature will be lower. This is due to the difference in air pressure. Based on this principle of water boiling at a lower temperature with decreased air pressure, we can achieve the same result by evacuating the heat pipe.

3. The heat pipe vacuum tubes used in solar collectors have a boiling point of only around 30oC. So when the heat pipe is heated above this temperature, the water begins to vaporize. This vapor rapidly rises to the top of the heat pipe and generates large amounts of heat.

4. During the operation cycle of the heat pipe, the flow of condensed liquid to the bottom relies on gravity and for this reason the heat pipe vacuum tubes do not work when horizontal and have reduced output when vertical. Jinyi recommends an installation angle with a range from 20 o to 80o in order to ensure optimal performance.

5. At room temperature the water in the solar evacuated tube forms a small ball shape. When the heat pipe is shaken, the ball of water can be heard rattling inside.

6. There are more than 20 manufacturing steps with strict quality control required to make a heat pipe vacuum tube.

Performance of Solar Evacuated Tube

1. The job of the heat pipes in the evacuated tubes is to transfer away the heat quickly. The capacity of the heat pipe must be greater than the evacuated tube's maximum output to avoid a bottle neck in the heat transfer chain. The average heat transfer capacity of our heat pipe vacuum tube is more than 110Watts. The maximum heat output of a solar evacuated tube is around 65Watts.

2. Material quality and cleanness play an extremely important role in the creation of a good quality heat pipe vacuum tube. The purity of the copper itself must also be very high, containing only trace amounts of oxygen and other impurities. If the copper contains too many impurities, it will leach out into the vacuum over time forming a pocket of air in the top of the heat pipe. This will affect the hottest point of the heat pipe to move downward away from the bulb where the heat transfer is required to occur.

Two models of Heat Pipe Vacuum Tube

|

Item No. |

Condenser Size |

Pipe Size |

| 812 009 004 |

Ф 14mm |

Ф 8mm |

| 812 009 005 |

Ф 24mm |

Ф 8mm |

As a professional solar evacuated tube manufacturer and supplier, we offer our clients normal vacuum tube, three target vacuum tube, heat pipe vacuum tube, U pipe evacuated tube and metal heat pipe. Till now, we’re able to annually output 20 thousand heat pipe solar collectors, 5 thousand U pipe evacuated tube solar thermal collectors, 10 thousand solar storage tanks, 10 thousand integrated pressurized solar heaters and 30 thousand non-pressure solar water heaters.